Continued on from the "me man me make fire" blog, this'll show the finishing of the lining, the chimney install, and the final placement of the burner..woo..

Finishing the lining

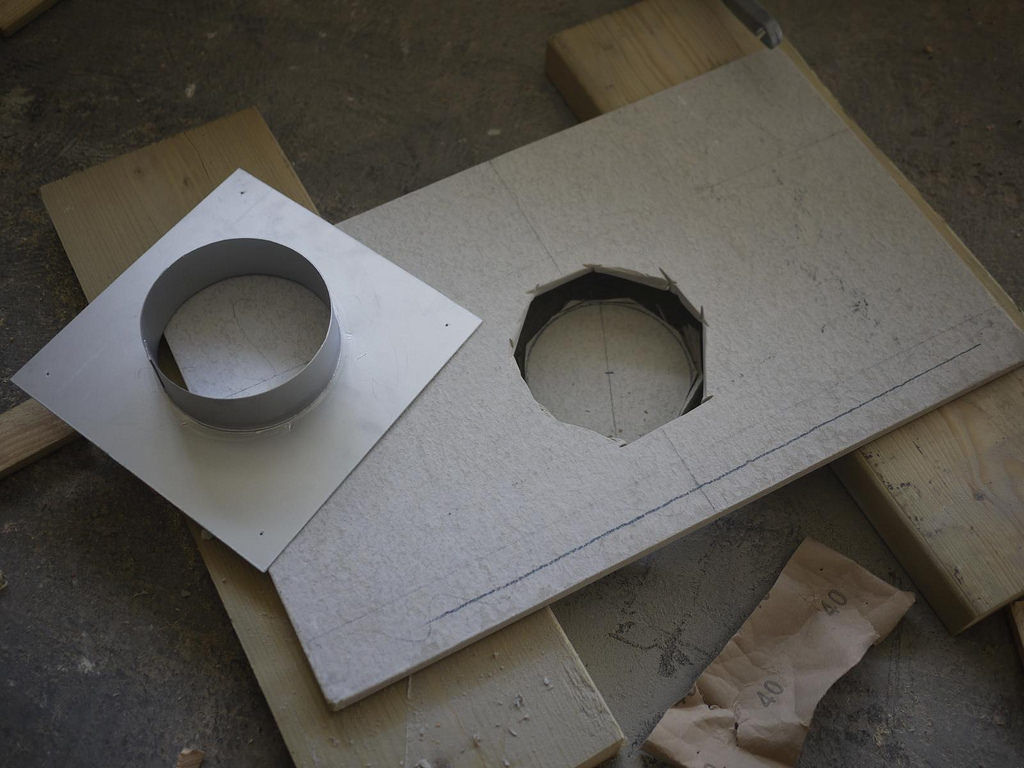

That was needed now was a way of getting the flue up through the top piece - I was planning on using a sort of metal 'collar' passing through the top of the fireplace - this was mostly aesthetic, and could mean that I didn't have to cut the cement board perfectly.

I think it came from eBay and I used stove paint to blacken it up a bit....

The stove paint was also used on the cement board too.

As always, a few pictures is worth a few thousand words:

The hearth...

There's rules and regs about this, and I opted for a nice safe distance of 30cm from the front of the burner for safety.

There's loads of different styles and methods for this (neither of which I'd done before) but I knew we wanted a contemporary look so opted for black slate.

Just round the corner is a good stone supplier, and just along the road (everything is round the corner or along the road..) is a stone mason who could cut the slate into the required lengths.

The slate was only about £30 for 3 tiles, and the cutting was about £25 (pricey, but meh..what can you do).

Thankfully my measurements were on the ball and it fitted in OK on the dry run!

Chim-chimeny..

This photo shows the first section of twin wall flue coming up from the 'twin wall to flexi liner' converter. Not all the stuff that can burn at least 6cm away. The copper's fine...

(clearly this protruding chimney is far too short - I misjudged the ceiling/roof thickness and needed to order another meter of pipework!

The finished business..

We're ready to paint and install the burner :-)

The pain looks really pink here - it's an odd colour that changes tone based on the light levels!

Despite being late summer/early autumn, we've already had several fires on the go! It's great to look at, and there IS a smug satisfaction from knowing that it was DIY install!!

As I said initially, I don't pretend to be an expert, but am happy to offer help and assistance if others are going down the DIY route!

RSS Feed

RSS Feed